By Jeremy Chisenhall

Temperatures reached 91 degrees in Mount Carroll, Illinois, on the day rescuers pulled Alejandro “Alex” Pacas and Wyatt Whitebread’s dead bodies from a grain bin.

The heat started it all.

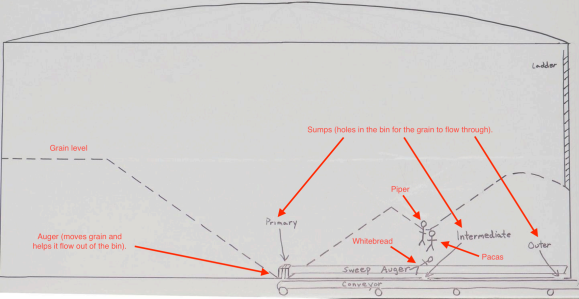

Whitebread fainted while “walking the grain,” in which a person enters the bin with an object like a piece of pipe or a shovel to try to loosen clumped-up grain, allowing it to flow out of the bin and onto a conveyer belt below.

None of the workers wore safety harnesses, and the corn beneath Whitebread gave way just before 10 a.m. Panicked, Pacas, 19, and Will Piper, 20, a coworker, tried to drag Whitebread out of the bin, said Catherine Rylatt, Pacas’ aunt and the founder of the Grain Handling Safety Coalition.

The two tried desperately to keep Whitebread from becoming a blip on the radar of a giant funnel of corn.

Just as they thought they grabbed Whitebread, the corn gave way beneath them, Rylatt said. An ocean of corn swallowed up Whitebread. Pacas and Piper became entrapped at that point, an OSHA investigation report stated.

Whitebread, 14, died first.

Entombed in corn, there was no saving him. He died from asphyxiation in just minutes.

Meanwhile, Pacas and Piper saw their friend quickly disappear, and now they tried to save themselves from the same fate. Piper’s head and neck remained above the grain, but the corn covered Pacas up to his neck.

Pacas and Piper asked Chris Lawton, a 15-year-old working with them, to alert the control room. A 911 call was made at 9:56 a.m., according to the Carroll County coroner’s report.

As they waited for the rescue team to arrive, Piper worked tirelessly to keep his best friend’s airway clear as Pacas remained suspended in a grain funnel.

Pacas was alive when rescue workers arrived, the OSHA investigation report stated. Rescuers called the parents. But they got no specifics, Rylatt said. All Pacas’ parents knew was that their son was in a grain bin. He could be the one whose head was above the grain, or he could be the one swallowed up.

They wouldn’t know for hours.

About 250 rescue workers spent those hours digging out two dead bodies and pulling Piper out alive, Rylatt said. The grain bin held 500,000 bushels, and it was about half full when the work began, the coroner’s report stated. That left about 14 million pounds of corn in the bin. The Mount Carroll ambulance and fire department responded to the call. They received help from 32 other adjoining agencies that included the fire and EMS agencies, a press release from the Carroll County Sheriff’s Office stated. Assistance also came from seven law enforcement agencies, the report stated.

Lifeline Helicopter, Medforce Helicopter, Stephenson County High Angle Rescue Team, German Valley Fire and Grain Tube Team, Carroll County Auxiliary, Lemons Ambulance and Star Ambulance assisted as well.

All in vain.

“So when the rescue people arrived, Alex was still alive,” Rylatt said. “From what I understand, he was still alive, but became engulfed. Will was trying to keep his airway clear and couldn’t because the grain kept flowing in, and he couldn’t keep up with it.”

He did not live for long.

The conveyor belt below the bin — used to carry the corn once passed through a funnel, had been stopped. But the grain still flowed at a trickle, the OSHA investigation stated.

Piper couldn’t keep a path clear.

Pacas suffocated. His time of death was about 10:15 a.m., the coroner’s report stated.

When they put Piper in a grain tube — a device used during rescues — to pull him out, they placed Pacas into the grain tube with him. Piper laid against his best friend’s dead body for hours as he tried not to suffocate from the grain crushing him. Rescuers pulled Piper out of the grain at 4:15 p.m., the OSHA investigation report stated. He was airlifted to a trauma unit.

“It was just devastating for him, and you know, to see his friend die and then be trapped inside a grain tube with the body against him, Will went through a really, really tough time afterwards,” Rylatt said.

Pacas and Whitebread’s bodies remained stuck for quite some time. Rescuers recovered Whitebread’s body at 10:15 p.m., and Pacas’ at 11:30 p.m., more than 13 hours after the incident began, the OSHA investigation report stated.

Pacas and Whitebread became two of the 26 reported grain entrapment fatalities in 2010, Purdue University’s Agricultural Safety & Health Program reported. And the number of reported grain entrapments for 2010 skyrocketed to 51, a 34% increase in entrapments from 2019.

Pacas and Whitebread’s deaths made up just 8% of grain entrapment deaths in 2010, but their deaths represented a significant microcosm of something more: grain entrapment deaths on small farms, where a lack of training and a lack of safety equipment can make farming far more dangerous.

Grain entrapments have claimed 125 lives in this decade, reported Purdue University and OSHA. Since the start of 2010, 275 grain entrapment incidents have occurred.

Pacas and Whitebread’s deaths in 2010 happened in the most catastrophic year in American history for grain entrapments, 26 deaths that, reported Purdue University and OSHA. That accounts for 20.8% of all reported grain entrapment deaths in this decade.

While America hasn’t seen a year that bad since, it hasn’t seen a steady decrease in entrapment cases or deaths. Relatively significant reductions occurred over the following two years — 27 cases and eight deaths in 2011.

The number of cases fell to 19 in 2012 (the lowest number of cases since 2003), while another eight deaths were identified that year, Purdue University reported.

The country has yet to see fewer than 10 reported deaths since then. There have been as many as 38 reported cases and 17 reported deaths in a single year (2014) since the decade lows that were seen in 2012.

There was an average number of 13.8 deaths per year from 2010 to 2018. The average number of total cases was 30.4 per year in that same time.

OSHA has just one reported death in its database for 2019, which happened on Feb. 22. It reported 30 cases and 15 deaths in 2018, the most recent complete year on record. That’s just slightly above the five-year average for reported cases, which is 28.8 — a 30% increase over 2017’s number of cases (23).

Pacas, Whitebread and their coworkers did not receive any kind of training on the hazards of entering a grain bin, the OSHA investigation report stated.

“Walking the grain” is prohibited under OSHA regulations. The trio also wore no protective equipment other than dust masks, the OSHA investigation reported.

Whether Pacas and Whitebread died on a “small farm” remains disputed.

Just four people worked in the bin, and they all knew one another, Rylatt said. The Occupational Safety and Handling Administration categorizes “small farms” as those that employ 10 people or fewer.

Haasbach LLC, the company that owned the grain bin in which Pacas and Whitebread suffocated, was not classified as a “small farm” operation, thus subjecting it to sanctions. OSHA classifies a “high penalty” fine as a fine that initially totals $40,000 or more. Haasbach’s initial fine was $555,000, OSHA inspection records showed. OSHA reduced the fine to $200,000. Haasbach paid that fine and a $68,125 fine to the U.S. Department of Labor, an OSHA news release stated.

The three families whose sons got stuck in the bin filed lawsuits against Consolidated Grain and Barge, also known as CBG Inc., the company that owned the bin, Rylatt said. Pacas and Whitebread’s families were awarded about $8 million each, Rylatt said. Piper’s family got about $1 million. A lawsuit was also filed against Grinnell Insurance, which was settled for about $1 million each, Rylatt said.

Mount Carroll and the surrounding areas summoned as much manpower as they possibly could to save the workers in the grain bin that day. But the death of Pacas and Whitebread made it clear that in a battle between manpower and time, time gets the upper hand.

Preventing an incident is what’s most important.

“It just happens very quick and I think that’s what most people don’t get,” Rylatt said. “There’s been a big push on the rescue side, and there’s nothing wrong with that. Give everybody grain tubes, train the volunteer fire departments. But the fact is in most cases you can’t even get there in time unless someone has stopped the flow of grain and is able to somehow stabilize that victim.”

This incident is what led Rylatt to create the Grain Handling Safety Coalition, a nonprofit, volunteer-based organization.

She wants to educate small farms on how to prevent incidents — rather than rely on rescuers.

“My husband was like, ‘You should do something about this,’” Rylatt said. “I had a background in government and had worked in nonprofits for several years, and it was just kind of like ‘Yeah, I should do something about this.’”

So she did.

“We have a pretty simple mission, and it’s just to prevent and reduce the incidents, injuries and fatalities across the grain handling spectrum through safety, education, training and awareness,” Rylatt said.

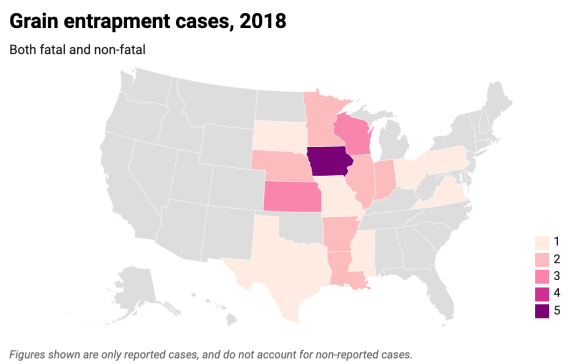

Grain entrapments occurred in 16 states throughout the country in 2018, and 83% of the cases were in the Midwest, reported Purdue University: Iowa (5); Kansas, Wisconsin (3); and Arkansas, Illinois, Indiana, Louisiana, Minnesota and Nebraska (2).

Indiana has had 165 total grain entrapment incidents — both fatal and non-fatal — since 1963, which is the most of any state. However, the report from Purdue University states that the reason is not because of greater danger but rather better monitoring of incidents.

“It is believed that this high number reflects more aggressive surveillance efforts in Indiana to document both fatal and non-fatal cases over the past 40 years, rather than an actual larger number of cases than other states,” the report stated.

“It is believed that Iowa, Illinois, and Minnesota should have had a substantially higher number of cases based on both total grain production and grain storage capacity.”

Most reported grain entrapment cases featured victims whose ages were not disclosed. However, among those that were disclosed, victims age 61-70 made up the most cases (5) and accounted for four deaths. The average age of grain entrapment victims was 42.

But “reported” cases of grain entrapment, both fatal and non-fatal, still don’t tell the whole story.

As of June 10, 2019, more than two-thirds of grain storage capacity in the U.S. is found on farms that are exempt from OSHA injury reporting requirement standards, Purdue University reported.

Farmers work long hours in hazardous conditions, almost always doing manual labor.

But that doesn’t mean accidents have to become acceptable.

“Farming is dangerous,” Rylatt said. “It is a tragedy. But it’s like there’s this acceptance out there that because farming is dangerous, we should expect a tragedy to occur. And it’s kind of like, ‘Well, it’s dangerous, but you can prevent the tragedies from occurring.’”

Enter Dale Dobson, a safety administrator for the Kentucky Department of Agriculture.

He conducts agricultural safety demonstrations and classes throughout Kentucky and owns one of every grain safety equipment item sold in North America.

But Dobson believes that preparedness goes beyond the equipment and safety training should primarily focus on how to solve problems on the fly.

“It ain’t about what you have in your hand as tools,” Dobson said. “There’s many different tools to use, I don’t care which one you have. But if you’re trained and prepared to know what to do, that’s how you can move forward.”

In his 21 years with the Kentucky Department of Agriculture, Dobson has taught farmers how to make grain rescue tubes out of trash cans, 55-gallon barrels, plywood and other materials often readily available. This education saved a life in Hardin County, Kentucky, when farmers in the area used their intuition to rescue an entrapped farmer, Dobson said.

“They had taken the training — they had taken the rescue classes,” he said. “But they had never raised the money, yet, to buy the equipment. They get there on the scene and the farmers and firefighters working together took a Rubbermaid garbage can, cut the bottom out of it, got in the bin, pressed it down around the guy and saved his life.”

Shortly after Dobson began his work with the KDA, his dad suffered severe arm injuries in a power shaft incident while doing farm work.

“He broke his arms into 1-inch pieces on the bone, and the only thing that was holding it on was skin,” Dobson said. “It just tore off. I found him. Anyhow, he went through 13 surgeries, seven weeks in the hospital. Doctor told him he would never use his arms again. But he was determined he would, and he did.”

The incident happened because the safety shield had been taken off of the shaft to perform maintenance, and it never got put back on.

Safety measures became Dobson’s target ever since.

It can be hard to make people understand the dangers of grain bins because there are fewer deaths from grain entrapment than there are from other more common incidents, like car wrecks or gun deaths.

However, that doesn’t mean the impact isn’t felt as heavily.

“You have a grain accident in a farming community, it devastates that community just the same as having an auto accident,” Dobson said.

Dobson added that car accidents can happen to anyone, while grain bin incidents only impact the agricultural community.

“Every adult in America is running around here in a vehicle, while only 2% of America is actually farming, and less than that is even in grain,” Dobson said.

Dobson advocates for farms to have ropes, harnesses and grain tubes on hand at their grain facilities to prevent incidents and resolve them.

“The number one rescue tool in the world is the human mind,” Dobson said in a video for Turtle Plastics, an environment health and safety product solutions company. “Take what you’ve got, take what you know, work as a team and get it done.”

His advocacy work led to major changes for Ryan Bivens, a farmer in Sonora, Kentucky.

“We have kind of safety procedures we follow just because we work so closely with Dale around here,” Bivens said. “You know, two men, we never go into a bin with just one person here. We always have another person here on standby. We’ve got safety equipment. We’ve got ropes, harnesses. We’ve got our own grain tube here.”

Bivens, owner and operator of Fresh Start Farms, said you can never avoid the danger that comes with farming, even with the safety precautions they’ve put in place.

“There’s no way to not get in a bin,” Bivens said. “It’s kind of like driving a car,” he said. “It’s dangerous to get in a car, but if you pay attention, know what you’re doing, you lessen your risk. Common sense will say ‘Don’t get in a car. Don’t drive a car.’ Well you’ve got to drive a car to get somewhere. That’s kind of like us getting in a bin.”

The danger of entering a bin gets joined by other factors that accompany farming.

“A lot of times we’re putting in long hours,” Bivens said. “You know, it’s nothing uncommon to put a 20-hour day in. We’re in the heat of the season. So you’ve got the fatigue of everybody for one — the dusty conditions. You know that’s how accidents happen.”

Bivens said that eventually someone must get in the bin.

But when becomes the question.

Grain flows like water when it gets poured into a bin, but it doesn’t level the way water does in a container. Grain bunches up with gaps between the layers.

Those bunches keep the grain from flowing properly, and workers have to get in the bin to break up the clumps.

“A farmer will get in there with a pipe or something and start jabbing at it, trying to break it up and get it to fall out and go into the auger,” Bivens said. “Well what happens is they get in there, and all of a sudden it gives loose, and then it comes in around them.”

The worker becomes trapped by millions of pounds of grain.

“If a person is buried up to their waist, and they’re able to still communicate with me, I’m going to try to help them out,” Bivens said. “If it’s a bad enough situation where I look in the bin and the person is gone, the first thing I’m going to do is call 911 and get first responders on the scene.”

Workers must shut off the auger — a screw-like device in the center of the bin that helps grain flow in a funnel shape — and try to begin the rescue process before the first responders get there.

This is where Dobson’s rescue and recovery training comes in.

“It’s a matter of having an old piece of metal or something that we can shove down in there to keep grain from flowing just to stop that flow of grain,” Bivens said. “Or if there’s a person down in there, and you don’t want them to sink anymore, you get them a 2-by-4 or a piece of pipe we were using, and lay it flat across the grain for them to hold on to keep them from going down any deeper.”

Fresh Start Farms also keeps milk crates around as a platform. The farmers can plant them into the grain for something to stand on top of without risking more shifts in the grain.

Once the first responders get there, they have to make sure they have the manpower and the equipment to complete the rescue, so having farmers on hand who know the equipment is very helpful, said Todd Bivens, a firefighter, first responder and Ryan Bivens’ brother.

A successful rescue requires calling the first responders as quickly as possible, but that doesn’t happen as often as it should.

“The biggest dilemma that most firefighters face nowadays is farmers try to do things on their own,” Todd Bivens said. “So typically, when we get the call, we’re already behind the eight ball. They may be an hour into the incident, it may be — there’s a lot of farmers out there now that are getting a lot better about calling 911 as soon as the incident happens.”

The rescue process takes hours, but every minute saved can save a life.

Responders must carry the rescue equipment into the bin’s doors at the top. The process gets reversed once the responders secure victim and try to carry the body out, Todd Bivens said.

The complexity of the rescue depends on the severity of the situation, Todd Bivens said. Some rescues can take days, especially in bigger bins where the victim is fully submerged. In this situation, emergency responders sometimes have to cut the side of the bin open and let the grain pour out.

“You’re looking at close to 120 tractor-trailer loads of grain in one of those bins, so depending on if you can still see them on top of the grain, it could be something as few as 20-to-30 (people),” he said. “If it’s something to where they’re sunk down in the grain, and you’re having to remove a lot of grain from that grain bin, it could be something to where you’re out here for a couple days working to recover a person out of that situation and it could be hundreds of people.”

Ryan Bivens said that his biggest grain bins hold 125,000 bushels of grain, which is about seven million pounds of corn. That would be about 125 tractor-trailer loads, he said. That’s enough to fill five Olympic-size swimming pools with more corn still left over.

Dobson’s safety demonstrations have greatly aided rescue operations when there’s a need to pull someone out of that much corn.

Another factor: a shortage of firefighters in rural areas.

Midwest states such as Iowa, Nebraska, North Dakota and South Dakota fall in the bottom quarter of firefighter employment rankings throughout all 50 states, data from the Bureau of Labor Statistics shows. This means farmers must know how to handle safety equipment.

Some of these farmers have also become first responders themselves.

“We need extra responders in this country,” Dobson said. “We’re short on rescuers. These farmers see that we’re short on things, and we’re getting some new firefighters. We’re getting a few firefighters that are farmers that know what it is and can be a specialist in that area.”

Organizations that are making efforts to improve awareness and safety in grain bins are only able to do so much. Nonprofit organizations, such as the Grain Handling Safety Coalition, have to rely on grant money.

“It’s not prevalent,” Rylatt said of grant funding. “It’s competitive to get it — you’re still relying on the industry to do a lot of the work and to make the changes that need to be made.”

Rylatt said her organization gets money from OSHA through the Susan Harwood Training Grant Program. OSHA offers grants to help people carry out projects that help to improve conditions in OSHA’s target industries, Rylatt said.

OSHA has worked with Rylatt’s organization with the Grain Elevator and Processing Society and the National Grain and Feed Association to create an alliance that partners to sponsor Stand Up for Grain Safety Week. The annual event happens in mid-April 2020.

It calls attention to training that improves safety in grain-handling workplaces.

“It’s great because this year I think it’s going to have an enhanced effect around the country,” said Ann Grevenkamp, a health and safety specialist for OSHA. “We’ve been able to bring in some other OSHA regions, so while it’s not all about OSHA because clearly we want to get people from the field and workers and employers and everybody together to do some training, to raise awareness, to get it out there.”

OSHA does the best it can to raise awareness and call employers to action when it comes to grain safety, but organizations like the Grain Handling Safety Coalition are able to specialize in that, which makes partnerships with OSHA valuable for both sides.

“It’s easier for them to spread the word than it is for us,” Grevenkamp said. “But they’re fantastic, and so they put things out in emails, and they have webinars.”

Stand Up for Grain Safety Week will continue to be a regular event for the foreseeable future, Grevenkamp said.

“I don’t think we’re looking at ceasing this any time in the future, so our goal is to just continue being here to get more and more participation.”

Grant availability also depends on the public’s perception of the dangers of grain, Rylatt said.

“After 2010, there were a lot of people getting grants, a lot of people concentrating on safety, and looking at the industry and saying, ‘You’ve got to make changes,’” Rylatt said. “Just like with anything, you know, after a few years it kind of wanes. You kind of saw that reflected in some of the statistics.”

There were eight grain entrapment deaths in 2011 and 2012, respectively, and numbers rose back into double digits in 2013. They haven’t dropped back below 10 since, Purdue University reported.

As efforts are made to raise grain safety awareness, the younger generation will be vital, Rylatt said. She said younger farmers are more used to the safety precautions the industry needs, including using safety harnesses and lifelines.

Others have been slower to adapt to greater safety recommendations and regulations. Some have seen OSHA as a hassle rather than an organization that improves safety.

“It’s time to take a step back and say, ‘OK, maybe in our mind they’re picking on us, but it doesn’t mean we don’t have safety issues to address, and a safety culture to address,’” Rylatt said. “So I think they’ve made progress, but I think there’s a ways to go.”

Rylatt said safety awareness will become increasingly important because the industry could see a lot of incidents in the near future.

The culprit: weather. The U.S. had its wettest 12 months on record ending April 2019, per data from the National Oceanic and Atmospheric Administration. Precipitation totals in 2010 were near the highest on record from 2000 to 2010 as well.

“We all know that next harvest is going to be bad because this harvest was bad,” she said. “So we’re looking at another situation like 2010 where this all started, where crops are going in wet. When they go in wet, they’re going to go out of condition, and there’s going to end up being more people going into the bins, and more hazards in terms of bin entry.”